Audi uses the wheelspeed-based system for the A3.

About a month ago, inspired by this thread on vwvortex, Ryan, Jim and I began discussing retrofitting TPMS to our A3s. I volunteered to be the test case, and we ordered the required parts soon after seeing this post by 'Theresias', who gave the part numbers and the programming changes that would be required. I'll reproduce the information here, but credit for initially describing it goes to Theresias. Thanks also to Jim (bassbiker) for his help, and especially for the use of his VAG-COM system. Parts were sourced from vagparts.com (pricing to be worked out soon).

Before you start:

You must check to see if your ABS controller is compatible with this mod.

Versions claimed to work are:

- 1K0 907 379 K

- 1K0 907 379 Q

- 1K0 614 517 R

Parts List:

Here are the parts that are needed. Note that the switch is slightly different for the single-DIN dash (e.g. with the Concert head unit) and the double-DIN dash (e.g. with the Symphony head unit, or Navigation).

Switch for single-DIN dash: 8P0-927-121-5PR

Switch for double-DIN dash: 8P0-927-121-A-5PR

Needed for either switch -

- 1x Plug (maybe available in US): 4D0-971-636-A

- 2x Wires for TPMS switch plug (available in US): 000-979-009

- 1x Wire for ABS plug (available in US): 000-979-131

Programming -

- VAG-COM (CAN-capable version) from Ross-Tech

-OR- - HPA VAD (with VAG module)(formerly known as ProDiag HD from Shade Tree Software).

Generic items -

- 18-gauge hookup wire, suggest blue, green, brown, black

- Butt-splice crimp-on connectors for 18-22 gauge wire (not larger) (min. 5 needed)

- Round lug connectors for 18-22 gauge wire (not larger) (min. 1 needed)

- Tap splice connectors for 18-22 gauge wire (not larger) (min. 1 needed)

- Wire stripping/crimping tool (just get one, don't mess around with pliers)

- Add-a-circuit MINI (the smaller fuse size) for obtaining power

- Heavy wire clotheshanger and 20-gauge steel 'safety wire', for fishing through the firewall

- LOTS of normal and mini-size zip-ties.

- Electrical tape (necessary), friction tape (optional)

- Various hand tools, (8mm nutdriver, small flat screwdriver, pliers, etc.)

Overview:

A pushbutton switch (Audi part) will be installed in the dash.

It will have 4 wire connections going to: +12V (black), Ground (brown), Central Electronics module (blue), ABS module (green).

The ABS module is in the engine compartment, on the right side of the firewall.

Once the physical parts are installed/hooked up, the feature needs to be activated in the software coding for the ABS module

Procedure:

Remove the fuse cover on the left side of the dash carefully, then remove the 1 silver bolt in there (attaching the lower dash panel) using an 8mm nutdriver. Remove 2 identical bolts from the lower part of that panel in the driver's footwell. Pull the panel straight towards the rear of the car, away from the dash. Don't try to 'peel' it off by pulling from the bottom, it has to go straight back pulling from near the top.

You will need some 'repair wire' parts from Audi, which can be obtained from your parts department. They are a length of wire with a connector (the same one) on each end. There are various connectors, for this project you will need part number 000-979-131, a female blade connector (one of those shown below), and two of part number 000-979-009, a tiny female pin connector. You cut the wires in half to give you two connectors/leads each which you will use at various points, and you can trim the wire down later as needed.

Repair wire:

Comparison of the two sizes of the repair wires used for this project, with part numbers.

Power (switched +12V) was conveniently obtained by using a piggy-back fuse arrangement in the fuse-panel. This is the 'MINI Add-A-Circuit' (FHM200BP) for the smaller fuse size, made by Littlefuse (standard fuse size packaging pictured below, but use the MINI one for this installation). I found them at a local auto parts store. You'll need a MINI one for this install. They hold two fuses each - the lower fuse is for the original circuit, and should be the amperage that was originally present in that slot. Just reuse the original fuse. The upper fuse is for the new circuit you're adding, and should be the appropriate amperage for that. It is EXTREMELY IMPORTANT that you install these devices in the fusebox in the correct direction - if you don't, the fuse winds up being downstream of the circuit, which is useless and potentially dangerous. You test this by plugging it into the fusebox and checking the voltage with and without a fuse in the upper position. If you still get power with the fuse not there, it's backwards.... For the A3 fusebox, having the pigtails pointing down is the correct orientation (but check it yourself to make sure).

Some of the factory wires for these circuits would be striped, but since I couldn't find striped wire I picked wire colours that correspond to the identifiable colours of the original colour code (e.g. for grey/green I used green). All wiring that I added is 18 gauge stranded hookup wire.

You will need some common tools, and a wire strip/crimp tool (don't try to substitute pliers). In addition to a roll of electrical tape, you should also have a roll of friction tape (a fabric-like, sticky-on-both-sides, electrical tape). For the connections you will need some 18-22 gauge crimp-on butt splices, and 18-22 gauge tap splices:

You have to get one wire through the firewall. Take a stiff wire clotheshanger and make yourself a tool about 60cm (2 feet) long with a large loop at one end for a handle. Poke the point of this wire through the grommet in the driver's footwell that is to the left of the clutch pedal, where there is already a wiring harness going through.

Keep pushing it through, and it should appear somewhere around the battery box. Bend a very small loop in the end of it, and attach something to it to pull back in. You can either pull the actual wire back in, or you can take another step like I did (there is a logic to it, work with me here...). Attach some 20gauge steel wire (e.g. aviation 'safety wire') and pull it back through the firewall into the driver's footwell.

Then attach the hookup wire to it and pull it through to the engine compartment:

...and route it between the two soft pieces behind the battery box to protect it, and zip-tie it in place:

Now you can simply tuck it behind the insulation on the firewall and run it across to the right side of the engine. When you get to where the gasket curves, you will need to pull up the gasket to work with it for the moment:

I again routed it between the soft insulation , and left a little excess behind the insulation. All of this is wrapped with friction tape and is hidden behind the insulation, shown exposed here for example only:

This photo didn't turn out as well as I thought, sorry. There is a plastic cable chase on the side of the engine compartment just below where this wire is, and it covers part of the wiring harness going to the ABS plug. There are four clips holding the cover on, I loosened three of them and ran the cable through the chase, then snapped it back together. Shown here held open so you can see the (green) wire running through.

Now you have to remove the ABS plug. There is a clip on top that pulls out (slides) UPWARDS ("1" in the photo). When you get it pulled out all the way, the plug pretty much falls off of the controller with no effort at all ("2" in the photo). Photo is of a MkV GTI, but is representative of the A3 for this purpose (image courtesy of team-dezent.at):

With the ABS plug detached from the controller, it doesn't move very far. The cap on the back of the plug has to come off. This image is deceiving, because it's clipped on pretty securely. You'll have to loosen the two clips at the back of the plug first (near the sliding clip), then the ones at the other end. Use a short-handled flat screwdriver. Sorry, no photo of this process:

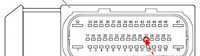

Locate the correct pin location on the face of the ABS plug, the part that plugs into the ABS controller:

For most manual transmission A3s and early DSG A3s without the 'Hill Hold' function, this should be Pin 27.

Most new DSG-equipped A3s have the 'Hill Hold' function, and will have a Red/White wire already in pin number 27. For those cars, the correct location is Pin 41. Do not disturb any already-existing wire in Pin 27 on those cars.

The middle row goes (from sliding clip end to the other end):

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31.

The bottom row goes (from sliding clip end to the other end):

32 (wide pin on the outside) 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 (wide pin on the outside)

View of the plug and the socket, for reference:

Look at the back side of the plug, where all the wires are, and find the pin number marking at the end of the middle (or bottom, as appropriate) row and count backwards from there. There should be no wire in the plug at that position originally. This is where we'll install one of the repair wire clips.

Indicating the location of Pin 27 on the face of the plug:

Indicating the location of Pin 41 on the face of the plug:

Virtually all of the Audi plugs have to be 'unlocked' before you can insert a new pin, like we're going to do. On this plug, look for the purple plastic. You will see a '+" shaped purple piece at one end, and a slot in the purple at the other end. This photo shows a screwdriver in the slot. Use the screwdriver to slide the purple plastic very slightly (about 0.5mm) towards the sliding-clip end of the plug until you hear/feel a 'click':

Use a nail in a pair of locking pliers to extract the rubber plug from position 27 (or 41, as appropriate) on the back of the plug, then use the same nail to pierce the rubber plug lengthwise to accomodate the wire.

Take the repair wire 000-979-131 and cut in in half to get a connector with a lead on it. Insert the lead through the rubber plug in the orientation shown here (larger connector shown for example only):

Insert the repair wire connector into the position 27 (or 41, as appropriate) of the ABS plug from the back side, until it clicks in firmly. It only fits in one way - you can figure it out. If you can't get it all the way in until it clicks, make sure you unlocked the purple part as described above. When finished, tt should look from the front just like the others in the plug, and you should seat the rubber plug into the hole behind it so that it looks like the other wires (make sure you slide the purple part the other way to 'lock' it again).

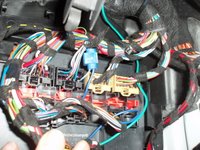

Use a butt-splice to join the wire you ran previously to the end of the repair wire you just installed in the plug. You'll need to do some trimming, and the splice should look like this:

Seal the butt-splice with electrical tape, and use small zip-ties to secure it to the heavy brown ground wires in the plug. In this photo, you can see how the green wire which was run down to the ABS plug was zip-tied securely to the harness on the way down:

Wrap the wiring harness going to the ABS plug with friction tape which will cover the new wire and zip-ties and will mimic the stock 'wrapped' appearance of the harness in that area.

Installation is the reverse of removal: Make sure the purple plastic on the plug is in the locked position. Reinstall the cap on the back. Pull out the sliding clip, position the plug on the controller, and push the clip in to lock the plug in place securely. Finished product shown here:

We're done outside. Now we move on to the interior portion.

Take two repair wires (part number 000-979-009) and cut them in half to obtain 4 pins with leads. Insert the leads into the 4 corners (pins 1, 3, 4, 6) of the plug (part number 4D0-971-636-A), and lable them:

- Pin 1: (BLUE) Central Electronics

- Pin 3: (BROWN) Ground

- Pin 4: (BLACK) +12v

- Pin 6: (GREEN) ABS

Make up the rest of your harness by bundling (with zip-ties...) the green wire coming through the firewall from the ABS controller with the brown, black and blue wires. You'll have to exercise judgement about routing under the dash and leaving enough extra to work with. Obviously, read and understand all of these instructions before starting, and map out where everything is going to go before you get started. In any case, you will get these four wires up and through the switch position in the centre of the dash. Trim the excess, and attach the corresponding wires to the leads from the plug with the butt-splices (you did label them like I said, right?):

Plug in the switch, and snap it into the dash:

Connecting to the Central Electronics control module isn't difficult, just annoying because it's in a tight spot. It's up under the dash, above and to the left of the clutch pedal.

First, let's get oriented to what is where on the module.

The controller should have a lable on it of 'Bordnetzsteuergerat'.

The side facing downwards has space for 8 plugs on it. A, B, C, D are on the first row, and E, F, G, H are on the second row. In the photo below, identify plug B (black, top row, one in from the left).

In the photo, notice the red plastic bar running side-to-side between the rows of plugs. You must slide it to unlock the plugs, otherwise the plugs do not come out. After you unlock it, you can release the tab on the plug to take it out.

You're going to connect to Pin 12 on Plug B. There are two possibilities - either there is a wire already in the plug in that postition, or there isn't. If there is (as was the case in my car), simply use a tap splice to connect to it. The factory wire for that position would be blue&grey, our wire is blue. The finished connection is shown in the photo.

(If there is no wire already in that plug position, you will need to use the other half of the 000-979-131repair wire left over from the ABS plug connection and install it Plug B position 12. There is a purple locking piece on the plug that will have to be unlocked before/relocked after installing the connector. This note is likely not needed, but is included for completeness.)

Once the blue wire is connected to position 12, make sure the plug is firmly clicked into the Central Electronics module and the red bar is back in the 'locked' position:

The last bit of the physical installation is power. Our black wire goes to the Add-A-Circuit MINI, which I placed in fuse position 8 with a 5A fuse (the other two Add-A-Circuit pieces in the photo are for my bluetooth handsfree kit).

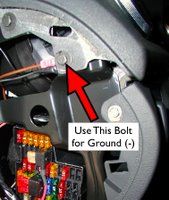

Our brown ground wire should have a round lug connector crimped on to it, and should be attached to this bolt. Sandwich it between the dash cover and the metal support and replace the bolt, for best electrical contact.

The dash can now be closed up. The physical installation is finished, all that remains is the coding.

Coding the module to make this work:

A VAG-COM system was used to enable the TPMS functions. In VAG-COM, go into the ABS module and edit the coding. You should subtract 16384 from the original coding. For example, if your original coding was 0021122 like mine was, subtracting 16384 from it gives a code of 0004738. Save this new coding and exit. The TPMS installation is now complete.

Check that your tire pressures are all correct.

With the car running, press and hold the 'Set' button. The TPMS symbol (see below) will illuminate, and then go out. When it goes out, release the button and you will hear a beep (like the low-fuel beep). The system is now reset and ready to learn your wheelspeed values.

The following is from Theresias' original post:

After connecting the button, check if it's working or not, you should use VAG-COM and ABS Measuring Block 018 Field 1.

How it Works:

First off, the new button only resets the TPMS learned values, after that it needs some driving distance to relearn these values. The learned values are adapted in several steps (speed ranges), each step (range) is devided into 2 thresholds in 2 stages (powered and rolling). You can check this using VAG-COM and read measuring block 031 in your ABS control module.

031,0,Tire Pressure Monitoring (TPMS) IV

; 0 = Nothing Learned

; 1 = Only 1st Threshold powered

; 2 = Only 2nd Threshold powered

; 3 = Only 1st Threshold rolling

; 4 = Only 2nd Threshold rolling

; 5 = 1st Threshold powered and rolling

; 6 = 1st Threshold powered and 2nd Threshold rolling

; 7 = 2nd Threshold powered and 1st Threshold rolling

; 8 = 2nd Threshold powered and rolling (Optimal)

031,1,Speed Ranges I

; 5?xxx = Speed Range 1 ( 15 - 70 km/h)

; 5x?xx = Speed Range 2 ( 70 - 100 km/h)

; 5xx?x = Speed Range 3 (100 - 130 km/h)

; 5xxx? = Speed Range 4 (130 - 160 km/h)

031,2,Speed Ranges II

; 5?xxx = Speed Range 5 (160 - 190 km/h)

; 5x?xx = Speed Range 6 (190 - 220 km/h)

; 5xx?x = Speed Range 7 (220 - 250 km/h)

031,3,Curve/Wheel,Recognition

; 5?x00 = Curve Recognition (0 = No Curve / 1 = Left or Right Curve learned / 2 = Complete Curve learned)

; 5x?00 = Wheel Recognition (0 = inactive / 1 = activ)

Optimal would be:

031 Field 1 = 58888

031 Field 2 = 58880

031 Field 3 = 52100

Also, because I know somebody is going to come across this....

Question: What is this item for? Byte 01 Bit 7 Tire Pressure Monitoring (Address 65) in the CAN Gateway. Is this related to this system, or a different one?

Answer: It is unrelated, leave it alone.

This was the first complete A3 TPMS installation in the US.

Having done this mod, I now have some ideas about how to pre-make the wiring harness differently, already cut to length with more soldered connections before installing in the car. If I get the chance to do this to someone else's car, I'll update this posting with any improvements to the process.

No comments:

Post a Comment