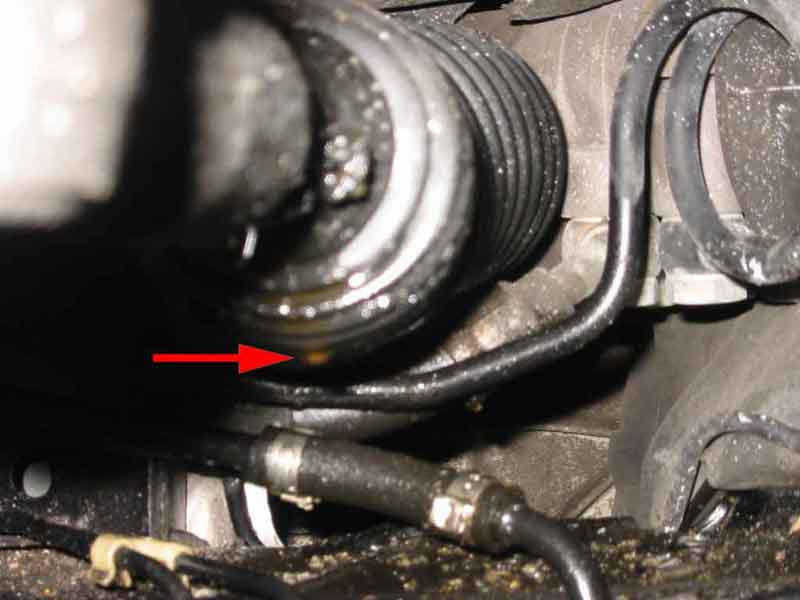

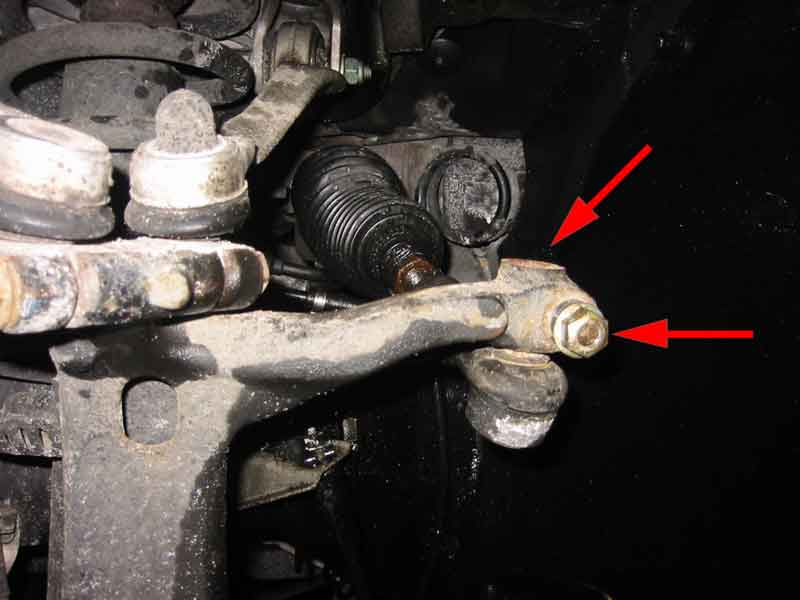

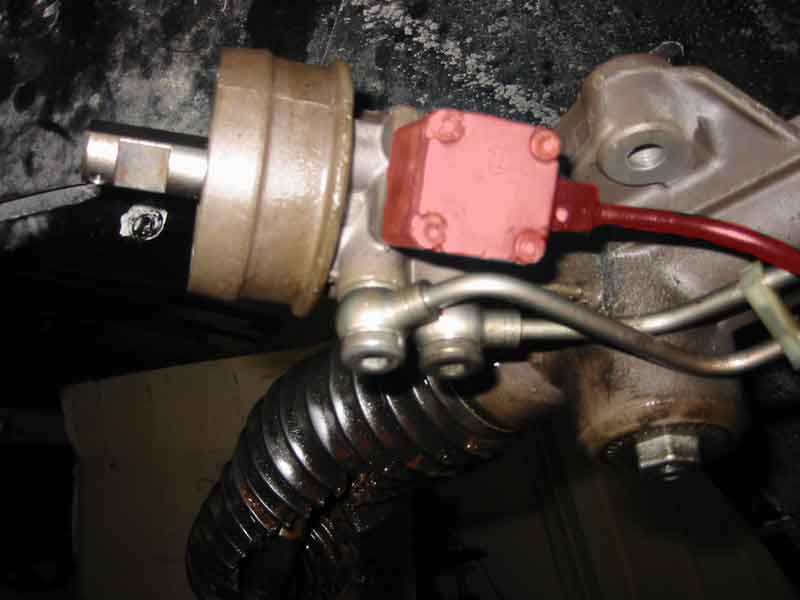

Power steering fluid leaking from boot! Notice brown color. Possible contamination. | If you have any leak of power steering fluid from your steering rack boots (the rubber accordion cone sticking into the upper part of the front wheel wells on most A-series Audi's), chances are an internal seal in the steering rack assembly has gone bad and the fluid is collecting in the boot. Once the boot fills with fluid, it seeps past the boot ties near the tie rod ends or it gushes out as the boots compress when the car is turning. Power steering fluid for the A8's are normally green, although if contaminated (major cause of leaks), they can take any color. There are a couple ways to confirm. One, is to try loosening the boot clamps and push the boot inwards, towards the rack assembly to compress the volume of the boot and power steering fluid should gush out. Another, is to watch the boot while another person starts the car, and while in park, turns the steering wheel lock to lock. The higher pressure of a running pump with the steering wheel at one extreme, as well as the resulting boot compression, should make the leak more apparent. If you are mistaken and the boots are dry, you can re-clamp the boots with plastic ties. |

I'd recommend going for a remanufactured rack to save some money. A new rack from the Audi dealer costs over $1200, and a remanufactured one can be had for up to 1/4 of that price, not including core deposit. You may find that racks come in a "long rack" and "short rack" variety. The "short rack" for the A8 usually has only the steering rack itself with the boots covering the included inner tie rods. Some offer "long racks", however, that also include a steering damper and a Servotronic module already bolted on, which may benefit from replacement and would otherwise have to be transferred from the old rack.

An additional thought is to replace the tie rod ends, if you've not already done so in the last 50-60k miles, since they wear out over time. They are relatively inexpensive and you'll already be paying for a steering alignment after this procedure, so might as well replace the tie rods, too.

What do I need?

The following is the procedure for replacing the steering rack on a '99 Audi A8 4.2, though the rack is the same from model years '97-'99, and the procedure should be the similar, if not the same.

The procedure should take 4-8 hours, though I believe the recommended billing time was 8 hours. Due to the difficult access to some of the bolts, it will take some elbow grease and patience. Not really for the timid. I would strongly recommend having another person to assist, and at least one of you should have a long, skinny arm to sacrifice.

Here are some of the tools you'll need, based on what I've used. The measurements in parenthesis are the approximate conversions of the ones I've used -- they may or may not work. Heck, they may even be rare and difficult to find, like the 16mm combination wrench:

|

Replacement parts:

|

Misc:

|

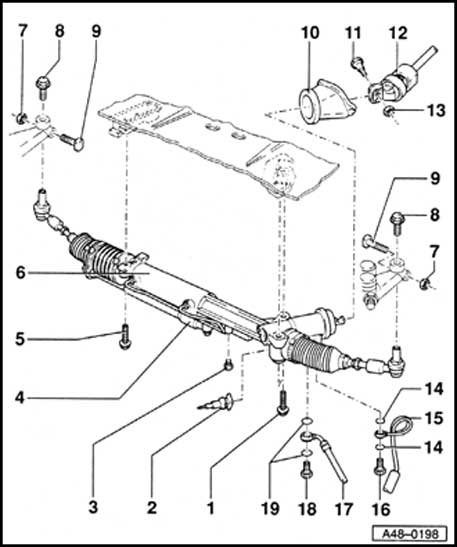

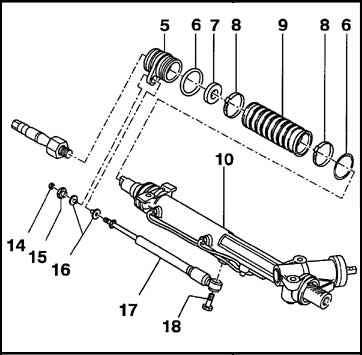

Overall Diagram:

Deceivingly simple, yes? Maybe if the rest of the car wasn't built, yet.**

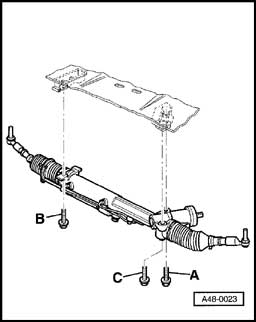

The three support bolts. Love them. Hate them.**

Procedure:

1. Disconnect steering u-joint.

With car off, twist steering wheel until it locks as close to horizontal as possible.You can either cut away the flap above the brake pedal (kind extreme) on the underside of the steering link or move it enough out of the way to give you good access. For access, remove driver side lower trim and diagnostics port (use flat-head screwdriver to release the 3 locking tabs from front face of trim), twist left trim bracket out of way (only need to unscrew 2 closest bolts, leave far 3rd bolt in place to act as an axis), pull air duct slightly forward until it hits the bracket you just moved. Laying in the driver side foot well looking up, you should be able to get a good peep at the steering column u-joint.

Pull out plastic trim pieces by hand: below steering wheel and strips on either side of wheel. |  Unscrew and remove the trim pieces. Disconnect diagnostics port. |

Unscrew 2 of 3 bolts on metal trim support. |  Unscrew and pull air duct forward. |

Should reveal the steering assembly u-joint. (Shown here, already disconnected.) |  Note, despite lack of nut in diagram, the nut really does exist.** |

After loosening and removing bolts, the joint can be pulled apart. However, try not to move the steering column more than necessary to move the linkage out of the way. Just a shade inwards towards the steering wheel and down towards the floor should give enough clearance to continue. Too far inwards and you could disengage the gears inside steering assembly, which is bad, very bad -- can you say new steering assembly?

|

2. Pull rubber seal around the rack's rotary valve forward into the driver compartment.

Pull out rubber seal. | Having an assistant push the seal from the driver's side wheel well helps greatly. |

3. Clamp hoses connected to power steering fluid reservoir.

Clamp both hoses coming from reservoir. | Use Audi's official hose clamps (VAG 3094) or fashion one yourself. For example, small C-clamps without any sharp contact edges. Or vice grips with the jaws duct taped to cover the sharp edges. |

4. Lift car.

Both sides if on blocks. Lift a little towards the car rear from the existing rubber reinforced lift points by the wheel well, so you can put the blocks on lift points. Be wary of brake lines (and suspension fluid lines, if applicable) near the lift points.

5. Remove both wheels.

Not completely necessary, but makes life MUCH easier. And you'll need all the ease you can get.I noticed cold weather makes the plastic lug caps brittle. Why plastic lug caps instead of solid bolt heads?

6. Disconnect both tie rod ends.

Disconnect tie rod end from wheel bearing housing. (Shown with vertical alignment bolt already removed.) | You can disconnect it from the wheel bearing housing or twist it out of the rack's tie rod. I think disconnecting it from the bearing housing makes things easier as it is one less thing to maneuver around when removing the rack. Note that both bolts need to be completely removed for the tie rod to be removed. Sometimes you can simply pull down on the tie rod and it will slip out. If it's a bit more stubborn and you need to hammer the tie rod down, don't hit the round rubber dust boots. Instead, use a tie-rod separator (pickle fork) or hammer at the larger diameter stem, just in front of the threads. It shouldn't take more that a couple light whacks.

|

7. Remove heat shield on passenger side.

Remove aluminum heat shield. | The pop-in inner attachment point on the steering damper is a pain to "pop" off, so it may be easier to first unbolt then slide outwards towards you until it slides off of the larger diameter piston housing onto the smaller diameter piston shaft.

|

8. Remove foam insulating panel at inside rear of driver's side wheel well, around the rack's rotary valve.

Remove foam insulating panel.** | Probably not necessary, but considering the tiny margin of space to pull the rack later, it's very recommended. Be careful when pulling, the foam can rip. The large circle disc-like nuts on the upper screws normally require a special tool, but they're not on tight. Just twist them with fingers and friction, or use a flat blade screwdriver.

|

9. Disconnect high pressure fluid lines from rack by removing both banjo bolts.

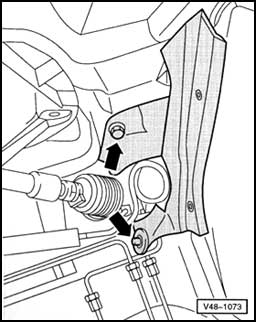

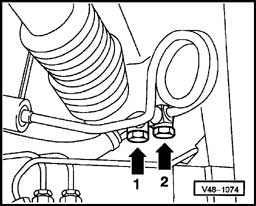

Remove bolts 1 and 2. Make sure you also remove seals, 2 for each bolt.** | For easier clean-up, place an old sponge just below the bolts prior to loosening to catch falling fluid from rotary valve. You can also remove hose bracket just behind the strut spring to let the hoses hang out of the way from the small opening allotted to the rack.

|

10. Loosen first rack support bolt to the car front, drivers side of the rack and pinion.

Tight, but accessible first rack support bolt. Loosen. | Small space, but easiest to remove. Use fine-tooth rachet. May want to keep it in to make third bolt removal easier.

|

11. Loosen second rack support bolt.

Put my hand where??? | The easiest place I've found to this horrid bolt was to go in from the top of the engine compartment. Remove the intake air duct between the air cleaner and the throttle valve. I call this new opening into the dark unknown: Satan's ***hole. It is full of sharp teeth and is hungry for your arm! Actually, it has one tooth, but it's vicious, I tell you -- it's one of the electrical connectors. I guess one COULD file the plastic corner down a bit. But that's no fun. Insert hand past wrist to mid-forearm into the hole, curl wrist around so hand bends toward rear of car, and grope for the support bolt around the passenger side rear of the hole. Insert homo-erotic joke here. Once the bolt location is established, insert a rachet wrench with proper hex bit with hand into hole. It will be hard to hold the wrench against gravity's pull and to twist the wrench at the same time, so an assistant is recommended. |

Teasingly in-accessible second rack support bolt from assistant's view. | Assistant can watch through passenger wheel well and direct hand. Also, assistant can reach in and secure the rachet head onto the bolt as you (try to) turn the rachet handle from the engine compartment hole. Feel the pain. Embrace the pain. Know Satan's ***hole.

|

12. Remove third rack support bolt.

Look up along the outer edge of that black suspension subframe. | Easiest approach I've found is to creep under the driver's side wheel well and look along the edge of the subframe closest to the wheel well, up through the side of the engine block. You'll need a u-joint rachet adapter (we taped it a couple times for stiffer resistance) and at least a foot long extension to get at this bolt. Viewed from the driver's side wheel well, it's basically on the far side of the rotary valve, close to the rack shaft. Check the steering rack support bolt diagram at the beginning of this procedure list for the position. The bolt hole also plainly visible on the picture of the Servotronic valve module later in this procedure list. Again, assistant can watch through the driver's side wheel well just behind the banjo bolts, help direct, and offer kind words of encouragement or bitter cynicism.

|

13. Remove the previously loosened second rack support bolt.

14. Remove the previously loosened first rack support bolt.

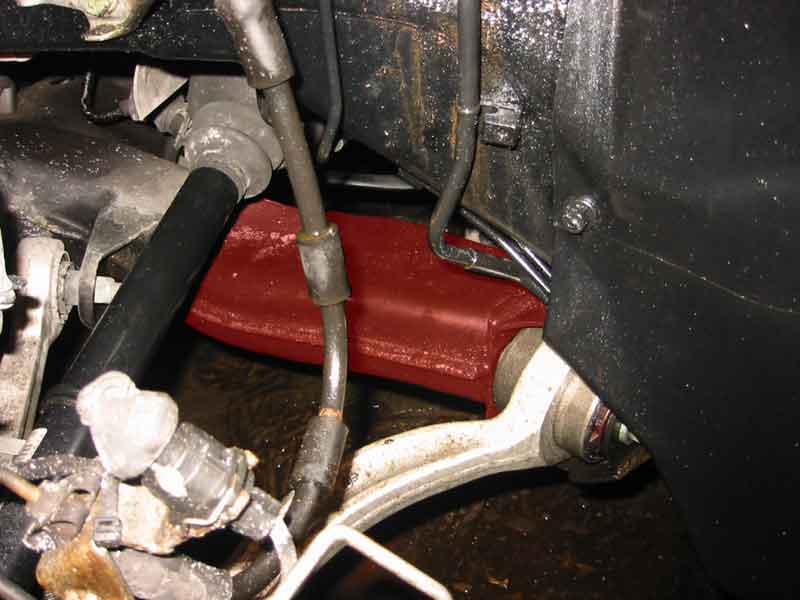

15. Partially slide out rack.

Partially removed rack to expose the Servotronic module. | Slide out rack past the rotary valve, until you have decent access to the Servotronic module without extending the attached module cable too much. When trying to get the rotary valve past the wheel well frame, twist the rack counter-clockwise and align the pinion butt with the little "bite" taken out of the frame on the lower car-front side of the opening. Might take a little jiggling, as the steering damper likes to catch on inner frame elements. Watch that you don't catch on cables and hoses. |

16. Remove or Disconnect the Servotronic module.

The rear of the rotary valve and the Servotronic module. | If your replacement rack already has a Servotronic module connected, don't worry about removing the module and just disconnect the module cable. To do this, you'll have to remove the driver's side inner plastic wheel well liner (rear) to access the cable connection. Follow the existing cable from the Servotronic module to find the connector and disconnect. To replace the module, start at the face of the module. There are four screws, two are Torx and two are Allen. Remove ONLY the Allen ones. Mine were on TIGHT and I ended up stripping the tiny Allen hole, so I had to hack-saw a line into the bolt head and then used a standard flat-head screw socket. Pull module out.

|

17. Slide out rack all the way.

Watch that you don't catch on cables and hoses.

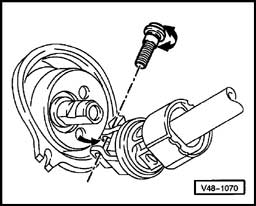

18. Transfer the old steering damper to the new rack.

Steering damper, parts 14-18.*** | If your replacement rack already has a steering damper... well then, aren't we special... skip to next step. Otherwise, you'll have to transfer the old steering damper on your broken rack to the replacement rack. Try not to twist the steering damper (#17) piston shaft while loosening the piston end nut (#14). Instead, turn the piston end nut while holding the washer nut (#16) still. The rubber washers and washer nut (both #16 in the diagram) are both almost black, but look closely: the nut is there. Note which end of the steering damper faces towards the rack shaft before unbolting (#18) it to transfer to the new rack.

|

19. Center the new rack using the centering hole and centering bolt.

I didn't have the special centering screw (VAG 1907), so I just watched through the centering hole for the "divot" on the rack shaft and then noted the length of the boot (the boot clamp to inner tie rod end on driver's side) and position of the u-joint steering stem at the centered state. There is a "cut-out" on the stem that allows a bolt to hold the u-joint, which should be pointing straight up when rack is centered.Or find another way to center the replacement steering rack after it is put in (see in later step).

Then transferred over the old screw plug (with lock-tite) from the old rack.

|

20. Slide in new rack part way to re-attach Servotronic module.

Try not to pull or push on the tie rods while putting in new rack.If your replacement rack already has a Servotronic module connected, reconnect the cable to the connector and replace the wheel well liner. It might be a good idea to duct tape the cable to the wheel well to minimize cable vibration (noise).

If you need to transfer the old Servotronic module to the replacement rack, now is a good time to replace Servotronic's fluid strainer and o-rings. The o-rings go directly on the nipple and the strainer just goes into the receiving hole. I confess I only changed the strainer -- my new rack happened to come with one.

(See above for bolt/nut specs.)

21. Slide in new rack all the way.

Try not to pull or push on the tie rods. The steering damper likes to catch on inner frame elements. May have to jiggle or lift it past them. Much easier with two people.

22. Attach and tighten (lock-tite) first support bolt.

Assistant holding up rack makes it easier. (See above for bolt/nut specs.)

23. Attach and tighten (lock-tite) second support bolt.

Assistant holding up rack makes it easier. Also, assistant could hold the rachet head on the bolt through the wheel well, while you swing the handle through Satan's ***hole. (See above for bolt/nut specs.)

24. Attach and tighten (lock-tite) third support bolt.

Get it on the same way you got it off, from under the car. To make it easier to keep the bolt on the hex driver, tape the bolt head to the driver head enough that the bolt will stay on for the trip, but not so much it will not come off with a good pull. (See above for bolt/nut specs.)

25. Re-tighten support bolts in the same order.

(See above for bolt/nut specs.)

26. Flush power steering pump of old fluid.

Put return high pressure hose end (with J-shaped connection, not the coiled one) in bucket. Open fluid reservoir cap and release hose clamp from power steering fluid reservoir's lower return hose. This should slowly empty out the reservoir and return hoses of the old fluid into the bucket. Re-clamp return hose connected to the reservoir when finished.Fill reservoir with fluid. Put plastic bag over coiled high pressure hose end where it was disconnected from the rack to contain the high pressure fluid spew. Remove clamp from upper reservoir hose feeding power steering pump. Place bucket around plastic bag. Poke hole in bottom of plastic bag to drain sprayed fluid into bucket. Have assistant start car and turn off car after 1 second of run time. Repeat fill/purge until you've ejected about a liter of fluid. Re-clamp same upper hose from reservoir feeding power steering pump.

Even though the hoses aren't connected to the rack and this procedure could probably be done before putting the new rack in, I waited until after getting the new rack in to purge, because I wasn't certain what starting the car with a disconnected Servotronic module would do to the module, or the diagnostic computer. Figured starting the car with a connected module would be better.

27. Re-attach high pressure lines.

Use new aluminum seals on both sides of both banjo bolts. Note that the part number for both lines may be the same, but the banjo bolts and seals are of DIFFERENT size. So, make sure the parts guy gives you 2 seals of each size. (See above for bolt/nut specs.)

28. Re-attach foam barrier on driver's side.

(See above for bolt/nut specs.)

29. Re-attach heat shield on passenger side.

Bolt first and then just reach in and "pop" the other end onto the steering damper piston housing. (See above for bolt/nut specs.)

30. Push rubber seal back around the rack's rotary valve showing through the driver's foot compartment.

Verify good positioning by looking through driver's side wheel well and adjust around neck of rotary valve if necessary.

31. Verify centered steering rack and re-attach steering assembly's u-joint.

There are a couple ways to verify that the steering rack is centered.The factory recommend way is with the special Audi centering screw (VAG 1907), which now has to be removed and replaced with the screw plug. As hard as it was to get to the support bolts, if you chose to go this route, I can only offer two words: good luck.

Or measure boot distance and compare to prior notes to approximate center steering position and check rack's u-joint connecting stem. The "cut-out" on the stem should be pointing up when rack is dead-straight. Use wrench to gently turn stem into proper position to mate with u-joint, since steering wheel never seems to lock in dead-straight position. Might be easier if steering lock is disengaged?

Or use a wrench or pliers to gently turn the rack's u-joint connecting stem from lock to lock, counting the number of revolutions. Reverse away from one of the lock positions half the total revolutions and you should be centered.

Or use your own method.

As you attach the u-joint bolt, note that because of the cam device in the u-joint bolt head, you'll have to take special steps in tightening:

- Insert bolt into u-joint and push in fully. Rotate so that the cam engages the flange.

- Thread nut fully onto the bolt and tighten until just barely snug.

- Rotate the BOLT head to tighten the flange using the cam device, while keeping nut still.

- Fully tighten the nut without allowing the bolt to turn.

(See above for bolt/nut specs.)

32. Tape-marker position of tie-rod position bolt on old rack and transfer to new rack.

Try to be as accurate as possible, but don't sweat it too much -- you're going to have to get an alignment, regardless.

|

33. Re-attach tie rod to wheel bearing housing.

The tie rod end stem that slips UPWARDS into the clamp of the wheel bearing housing has a "cut-out" portion. Align the cut-out portion of the stem so that it faces the horizontal bolt hole; it will be difficult to put the horizontal bolt in without this properly aligned. This is also a safety feature so that the tie rod will not slip out should the bolt loosen.Replace the self-locking nut. Notice that the horizontal bolt head has only one straight edge. Align this properly with the straight edge beveled into the back of the wheel bearing housing. Best to simply align the bolt head and press against the housing, the beveled edge will help the bolt remain still while you thread the self-locking nut.

(See above for bolt/nut specs.)

34. Clean.

Learn to appreciate brake cleaner. WD-40 works well, too. But don't use it on surfaces that rely on friction, like bolt threads, tie rod stems, and the brake system.Clean and dry areas around pump, rack, and hoses to make leaks easier to spot.

35. Bleed steering system of air and check for leaks.

The Bentley repair manual recommends the following procedure to bleed the power steering system:- Check hydraulic oil level and top off if necessary.

- Raise vehicle until front wheels are free.

- Start engine briefly. (max. 2 seconds) The pump must not draw in any air, the steering wheel must not [be] moved under any circumstances. Waiting time between individual engine starts approx. 30 sec.

- Check hydraulic oil level and top off if necessary.

- Repeat [above] procedure until the oil level remains constant.

- Turn steering wheel from lock to lock 10 times with engine switched off.

- Check hydraulic oil level and top off if necessary.

- Start engine.

- Turn steering wheel from lock to lock 10 times.

- Check hydraulic oil level and top off if necessary. Any remaining air in the steering system will dissipate when driving over the next 10-20 km (6-12 miles).

36. Re-attach wheels.

Don't forget the plastic lug caps.

37. Lower car.

38. Check again for leaks.

Check the power steering system:- Start engine.

- Turn steering wheel from lock to lock 10 times.

- Check hydraulic oil level and top off if necessary.

- Check all hoses, pump, and rack for leaks.

39. Test drive and check for leaks.

Nothing high-performance, mind you. Your wheel alignment is most likely way outta whack and will compromise your ability to take sharp turns at high speed. Not to mention tread wear. Just drive around the block. Listen for additional odd noises. Feel for any additional odd vibrations.

40. Get alignment.

Dealer charges about $150-170, depending on his mood. A respected mechanic once told me that Audi's (and other import luxury cars) have a complex alignment procedure that also requires tools that your local JiffyLube won't have. JiffyLube can set your steering wheel to point straight as your tires point straight, but there is more involved. Not sure what the "more involved" means, exactly... but I've been going to the dealer for the alignment, anyway.

1 comment:

Wow that is major work. I have a 1992 Audi 100 Quattro it looks like a similar process. My boots are split.

Post a Comment